What Are the Latest Innovations in Silage Management Machinery?

Feed spoilage ruins profitability while labor shortages cripple daily operations. Modernizing equipment resolves these bottlenecks by boosting efficiency plus preserving nutrient density. We manufacture industrial-grade agricultural solutions trusted by thousands worldwide for superior fodder processing.

Table of Contents

- 1. How do advanced harvesting technologies upgrade Silage Management Machinery performance?

- 2. Why is specialized filling equipment critical for Silage Management Machinery?

- 3. What solutions does Silage Management Machinery offer for covering clamps?

- 4. How are automated emptying systems changing Silage Management Machinery?

- 5. What role do IoT and data play in modern Silage Management Machinery?

- 6. How can drones enhance the capabilities of Silage Management Machinery?

- 7. In what ways does Silage Management Machinery address operator safety?

- 8. How does new Silage Management Machinery contribute to sustainability?

- 9. What factors should drive your selection of Silage Management Machinery?

- 10. How does upgrading Silage Management Machinery impact overall ROI?

- FAQ

1. How do advanced harvesting technologies upgrade Silage Management Machinery performance?

Precision sensors for optimal cutting length

Harvesting tech has evolved significantly past simple mechanical chopping. Here is the deal: Precise cut length determines how well your silage ferments plus how easily livestock digest it. New grass chopper machine models utilize infrared sensors for real-time crop analysis. These sensors adjust cutting mechanisms instantly based on moisture content. If stalks are too dry, cutting length decreases automatically for better packing. This technology prevents air pockets which cause spoilage. Farmers using sensor-equipped harvesters report consistent fermentation across their entire clamp.

Does automation reduce harvest waste?

Human error during harvest often leads toward missed rows or inconsistent chop quality. Automation fixes this problem permanently. GPS guidance systems steer harvesters with centimeter-level accuracy. This precision ensures every stalk gets collected efficiently. Automated spout control directs crop flow perfectly into trailers without spillage. Operators can focus upon monitoring machine health rather than steering. Reducing waste at this stage preserves maximum tonnage for storage.

Fuel efficiency in modern forage harvesters

Fuel costs eat directly into farm margins. Manufacturers now design engines specifically for variable load requirements. You might be wondering how this works. Smart engine management systems lower RPM during light work but boost power immediately when hitting dense crop patches. This dynamic response saves diesel without sacrificing throughput. Newer hydraulic systems also reduce parasitic power loss significantly. Less fuel burned per ton means higher profit per acre.

2. Why is specialized filling equipment critical for Silage Management Machinery?

The role of low center-of-gravity vehicles

Standard tractors often struggle upon steep silage clamps. They slip easily and fail achieving necessary compaction density. But here is the kicker: Specialized vehicles like PistenBully pushers solve this specific challenge. These machines feature wide tracks distributing weight evenly while maintaining immense traction. Their low center of gravity allows safe operation on steep inclines where wheeled tractors might roll over. Better stability means operators can push fodder higher safely.

Working safely on steep clamp angles

Compaction removes oxygen which spoils feed. Achieving high density requires driving heavy machinery over loose forage repeatedly. Specialized fillers climb 40-degree slopes effortlessly. This capability ensures edges get compacted just as tightly as the center. Loose edges are notorious for developing mold pockets. Eliminating them preserves tons of feed annually. Dedicated clamp machines transform dangerous tasks into routine operations.

Can dynamic blades improve leveling speed?

Moving tons of green chop requires immense force. Standard loader buckets often dig in or leave uneven piles. Dynamic blades adjust hydraulically to float over material or cut through piles aggressively. Ready for the good part? Vibration features in some blades help settle forage instantly during spreading. This micro-vibration removes trapped air faster than weight alone. Level clamps facilitate better sealing later on.

## Comparison of Filling Methodologies

| Feature | Standard Tractor | Specialized Compactor | Benefit |

|---|---|---|---|

| Stability | Moderate | Very High | Reduces rollover risk significantly |

| Compaction | Tire Width Limited | Full Track Width | Removes more oxygen pockets |

| Slope Handling | Max 20-25 Degrees | Up to 45 Degrees | Maximizes clamp capacity |

| Speed | Slow cycles | Fast cycles | Keeps up with foragers |

| Fuel Usage | High RPM needed | Optimized torque | Lowers operational overhead |

3. What solutions does Silage Management Machinery offer for covering clamps?

Mechanized handling of tyre sidewalls

Covering a massive clamp traditionally involves grueling manual labor. Workers throw hundreds of heavy tires by hand. Think about it: This backbreaking work causes injuries plus consumes valuable time. Innovations like the TYRESHIFT system mechanize this entire process. It attaches onto a loader headstock acting like a slow conveyor for tires. One operator places sidewalls accurately without leaving the cab.

Reducing manual labor in grid placement

Placing weights in precise grids ensures wind cannot lift plastic sheets. Mechanical placers deposit weights at exact intervals automatically. This consistency protects the oxygen barrier film underneath from tearing. Manual placement often results in gaps where air enters. Machines don’t get tired or sloppy near the end of a shift. Consistent weight distribution guarantees anaerobic conditions remain intact.

Is the covering process becoming fully automated?

While full automation isn’t standard yet, semi-automated systems are changing the game. Some new rollers unroll plastic sheeting while simultaneously weighing it down. Here is a secret: Combining tasks reduces passes over the clamp. Less traffic means less chance of tearing thin barrier films. Future systems may utilize autonomous rovers for maintaining cover integrity throughout storage periods.

4. How are automated emptying systems changing Silage Management Machinery?

Integrating defacers with vacuum transport

Feedout faces are prone to secondary fermentation if managed poorly. Here is the real story: Automated systems like Wasserbauer now combine defacing with vacuum transport. A robotic unit shaves silage off the face cleanly. This shaving action prevents air from penetrating deep into the stack. Vacuum tubes then suck loose feed directly into mixers. This closed loop minimizes exposure to contaminants and pests.

Streamlining the feed-out process

Traditional loading involves starting a tractor, hitching a wagon, and making multiple trips. Automated kitchens eliminate these steps entirely. Systems run on timers to load mixers before farmers even wake up. Consistent loading rates ensure rations remain nutritionally balanced every single day. Livestock respond well towards consistent feeding schedules. Automation guarantees this consistency regardless of labor availability.

Can robots replace traditional mixing wagons?

Large mixing wagons are overkill for smaller herds. Autonomous feeding robots scale down this technology effectively. These small units mix individual batches for specific pens. You might be surprised: They navigate barns using lidar sensors without human guidance. Electric drive systems lower noise levels significantly inside barns. Cows experience less stress during feeding times.

5. What role do IoT and data play in modern Silage Management Machinery?

Real-time monitoring of moisture and heat

Spoilage generates heat long before mold becomes visible. Wireless probes buried inside clamps transmit temperature data constantly. Here is why this matters: An alert on your phone allows immediate intervention before tons of feed rot. IoT sensors also track local weather conditions affecting feed stability. Knowing internal clamp conditions prevents guesswork during feedout.

Predictive maintenance using smart sensors

Breakdowns during harvest cost thousands per hour. Smart machinery predicts failures before they happen. Vibration sensors on bearings detect minute changes indicating wear. Control units notify dealers automatically when parts need replacement. This is huge: Technicians arrive with correct parts before the machine stops working. Uptime is critical for securing quality forage.

Why is data analytics vital for feed quality?

Data transforms raw numbers into actionable decisions. Yield maps show which fields produce highest quality crop. Fermentation logs reveal how packing density affected final pH levels. Farmers use this historical data for refining future harvests. Continuous improvement requires accurate measurement. Analytics provide the yardstick for success.

## Data Points Monitored by IoT Systems

| Metric | Sensor Type | Benefit |

|---|---|---|

| Temperature | Wireless Probe | Detects early aerobic instability |

| Moisture | NIR Sensor | Adjusts harvest timing accurately |

| Vibration | Accelerometer | Predicts mechanical bearing failure |

| Density | Pressure Plate | Ensures adequate air exclusion |

| GPS Location | Satellite | Maps yield variation precisely |

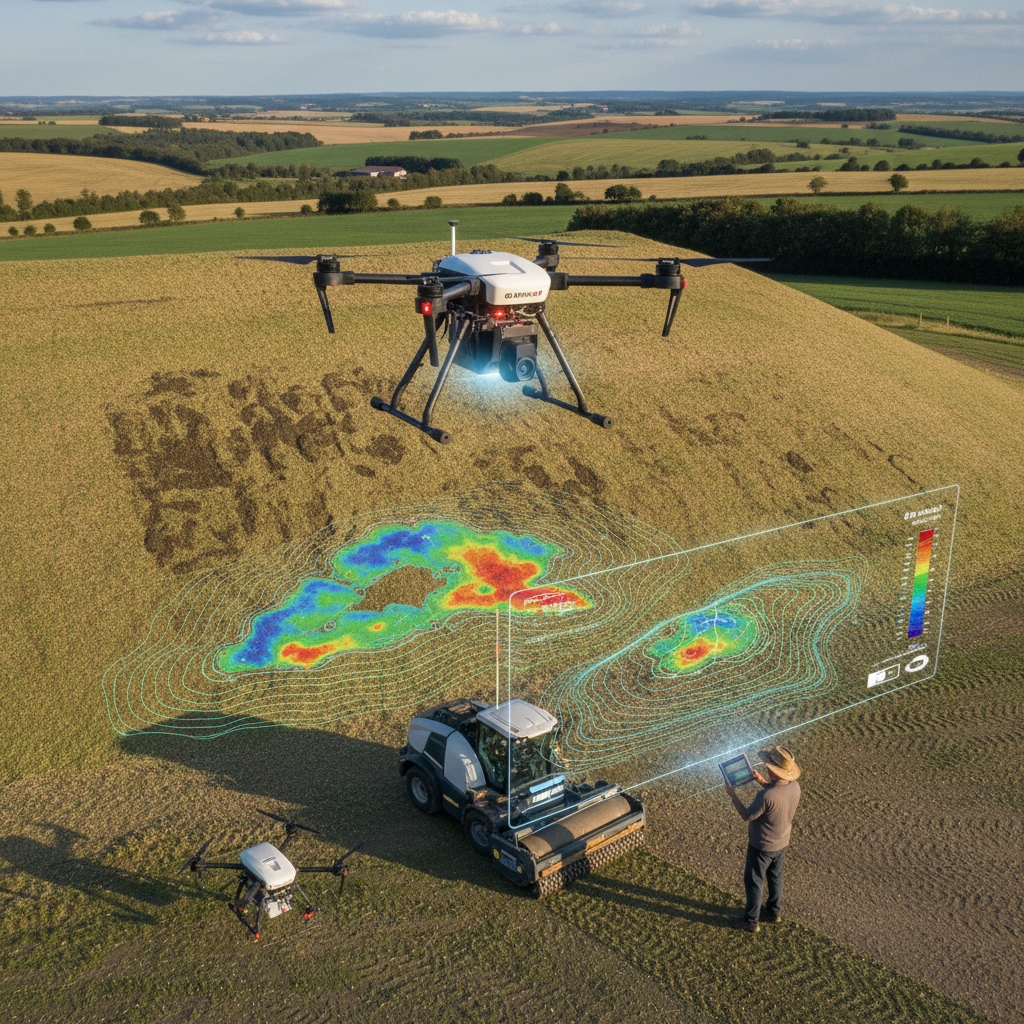

6. How can drones enhance the capabilities of Silage Management Machinery?

Aerial analysis of uneven compaction

Ground-level views hide many sins. Drones equipped with thermal cameras see what eyes cannot. Check this out: Cool spots on a thermal map indicate loose packing where air enters. Farmers use these aerial maps for directing compactors towards problem areas immediately. Fixing density issues during filling saves feed later. Thermal imaging provides x-ray vision for your silage clamp.

Identifying early signs of spoilage from above

Plastic covers damage easily from birds or hail. Small holes let in oxygen which ruins feed rapidly. Drones fly autonomous patterns scanning covers for punctures. High-resolution cameras spot tears invisible from the ground. Early detection allows patching before water penetrates the stack. Regular aerial patrols secure your investment cheaply.

Mapping clamp volume and density accurately

Estimating feed inventory is notoriously difficult. Drones use photogrammetry for creating 3D models of silage piles. Software calculates exact volume within minutes. Here is the best part: Combining volume with density data gives precise tonnage counts. Knowing exactly how much feed you own prevents shortages in winter. Accurate inventory data improves cash flow planning.

7. In what ways does Silage Management Machinery address operator safety?

Stability features for uneven surfaces

Farms are rarely flat. Top-heavy machinery poses severe rollover risks on silage piles. Our heavy-duty chaff cutter designs incorporate wider wheelbases for maximum stability. Safety comes first: Low mounting points for engines keep center of mass near the ground. Gyroscopic sensors can cut engine power if tilt angles become dangerous. Preventing accidents protects both staff plus equipment.

Reducing physical exposure to moving parts

Old machinery often had exposed belts plus gears. Modern designs enclose all moving components behind steel guards. Safety interlocks prevent covers from opening while blades spin. You need to know this: Automatic feeding systems keep hands far away from intake rollers. reducing human interaction with cutting mechanisms saves limbs. Safety compliance is built directly into hardware.

Are automated systems safer than manual operation?

Fatigue causes most farm accidents. Automation removes tired humans from dangerous environments. A robot pusher never gets distracted or sleepy. Remote control systems allow operators to stand safely away from hazard zones. Removing people from the equation eliminates most injury risks. Technology protects your most valuable asset: your team.

8. How does new Silage Management Machinery contribute to sustainability?

Lowering emissions with efficient engines

Diesel exhaust regulations are getting stricter globally. Tier 4 engines use advanced filtration for reducing particulate matter. Here is a fun fact: Some new electric chaff cutter models run entirely on grid power. This eliminates local emissions completely inside barns. Electric motors are also 90% efficient compared towards 40% for diesel. Clean air creates healthier environments for livestock.

Reducing feed waste through precision handling

Waste is an environmental/financial double whammy. Growing crop requires fertilizer, water, plus fuel. Throwing away rotten silage wastes those resources. Listen to this: Precision processing machinery reduces waste from 15% down towards 2%. Better cutting plus packing preserves more calories per acre. Efficiency is the truest form of sustainability.

Can better machinery lower overall energy inputs?

Processing tougher crops like Napier grass demands high torque. Old machines brute-forced this with massive engines. New designs use inertia flywheels for maintaining momentum efficiently. Hybrid drive systems store braking energy for power bursts. Smart engineering does more work with less kilowatts. Lower energy bills improve your bottom line directly.

9. What factors should drive your selection of Silage Management Machinery?

Assessing capacity against operational size

Buying too small causes bottlenecks; buying too big wastes capital. Here is the trick: Calculate your peak hourly requirement during harvest windows. A factory-direct agricultural machinery supplier can match specs perfectly towards your needs. Ensure the machine handles your specific crop type efficiently. Matching throughput prevents costly delays.

Compatibility with existing farm infrastructure

New machines must fit your current reality. A massive commercial unit might not fit through your barn doors. Don’t ignore this: Check power requirements against your grid capacity. Diesel units offer flexibility for remote sites without electricity. Ensure loaders can reach hopper heights comfortably. Integration prevents expensive modification headaches later.

Is the equipment scalable for future growth?

Farms tend growing over time. Your machinery should grow alongside you. Modular designs allow upgrading motors or blades later. Consider this: Resale value matters for future upgrades. Top-tier brands hold value better than generic alternatives. Investing wisely now saves capital expenditure tomorrow. Scalability ensures long-term operational viability.

## Machinery Selection Matrix

| Factor | Small Farm ( <50 Head) | Commercial Operation |

|---|---|---|

| Power Source | Electric (Single Phase) | Diesel / 3-Phase Electric |

| Throughput | 500-1000 kg/hr | 3+ Tons/hr |

| Mobility | Portable / Wheel-mounted | Static / Tractor Mounted |

| Automation | Manual Feed | Conveyor / Robot Feed |

| Maintenance | DIY Friendly | Service Contract Needed |

10. How does upgrading Silage Management Machinery impact overall ROI?

Calculating savings in labor man-hours

Time is your most expensive resource. Manual chopping consumes 40+ hours weekly for mid-sized herds. Here is the payoff: Mechanization cuts this down towards 5 hours. That is 35 hours released for other productive tasks. Calculate hourly wages saved annually against machine cost. Most units pay for themselves within months.

The correlation between feed quality and yield

Cows produce milk based upon nutrient intake. Poorly cut silage digests slowly. Get this: Precision chopped fodder improve milk yield by up towards 10%. Better digestion means more energy for milk production. Higher yields multiply revenue daily. Quality machinery boosts income directly.

Does reduced spoilage justify the capital cost?

Spoilage is invisible money burning. Losing 15% of your stack is standard with poor management. Bottom line: Reducing waste reduce fodder waste towards 2% saves thousands in replacement feed costs. You grew that crop; you should keep it. Spoilage reduction alone often covers finance payments. ROI calculations prove quality pays.

## Sample ROI Calculation (150 Head Dairy)

| Expense Category | Manual / Old Tech | Modern Machinery | Annual Savings |

|---|---|---|---|

| Labor Cost | $20,000 | $4,000 | $16,000 |

| Feed Waste | $15,000 (15%) | $2,000 (2%) | $13,000 |

| Milk Revenue | Baseline | +$25,000 (Yield Bump) | $25,000 |

| Maintenance | $3,000 | $1,000 | $2,000 |

| Total Benefit | — | — | $56,000 |

Conclusion

Upgrading silage machinery transforms farm economics completely. We explored how precision harvesting, automated filling, and smart data integration ISO 9001 certified manufacturer standards reduce waste significantly. The takeaway is clear: Modern equipment isn’t an expense; it is a profit generator. Stop letting spoilage and labor costs drain your bank account. Invest in proven technology today for securing your farm’s future.

FAQ

Q1: What is Silage Management Machinery?

Silage Management Machinery refers towards a range of specialized equipment designed for harvesting, processing, storing, and feeding fermented fodder crops. This category includes forage harvesters, chaff cutters, compaction vehicles, and automated feeding systems. These tools aim specifically for maximizing feed quality while minimizing labor inputs.

Q2: How does automated silage covering work?

Automated covering systems use machinery for unrolling oxygen barrier films and placing weights without manual lifting. Devices like the TYRESHIFT mechanically place tire sidewalls onto the stack. Other systems might use automated rollers for dispensing plastic sheeting evenly. This reduces physical strain upon workers and ensures consistent seal quality.

Q3: What solutions does Silage Management Machinery offer for covering clamps?

Modern machinery offers mechanized solutions like hydraulic sidewall placers and automated sheet dispensers. These tools speed up the covering process significantly immediately after filling. Faster covering prevents oxygen exposure which causes spoilage. They also ensure weights get distributed in precise grids for wind protection.

Q4: How are automated emptying systems changing Silage Management Machinery?

Automated emptying systems, such as robotic defacers, remove feed from the clamp face cleanly without disturbing the remaining stack. Vacuum or conveyor systems then transport this feed directly into mixers. This automation eliminates the need for daily tractor loader work. It ensures fresh feed is delivered consistently without human error.

Q5: What role do IoT and data play in modern Silage Management Machinery?

IoT sensors monitor critical metrics like moisture, temperature, and density in real-time. This data helps farmers make informed decisions about harvest timing and storage management. Analytics identify trends in machine performance and feed quality. Connectivity allows for predictive maintenance, preventing costly breakdowns during critical work windows.